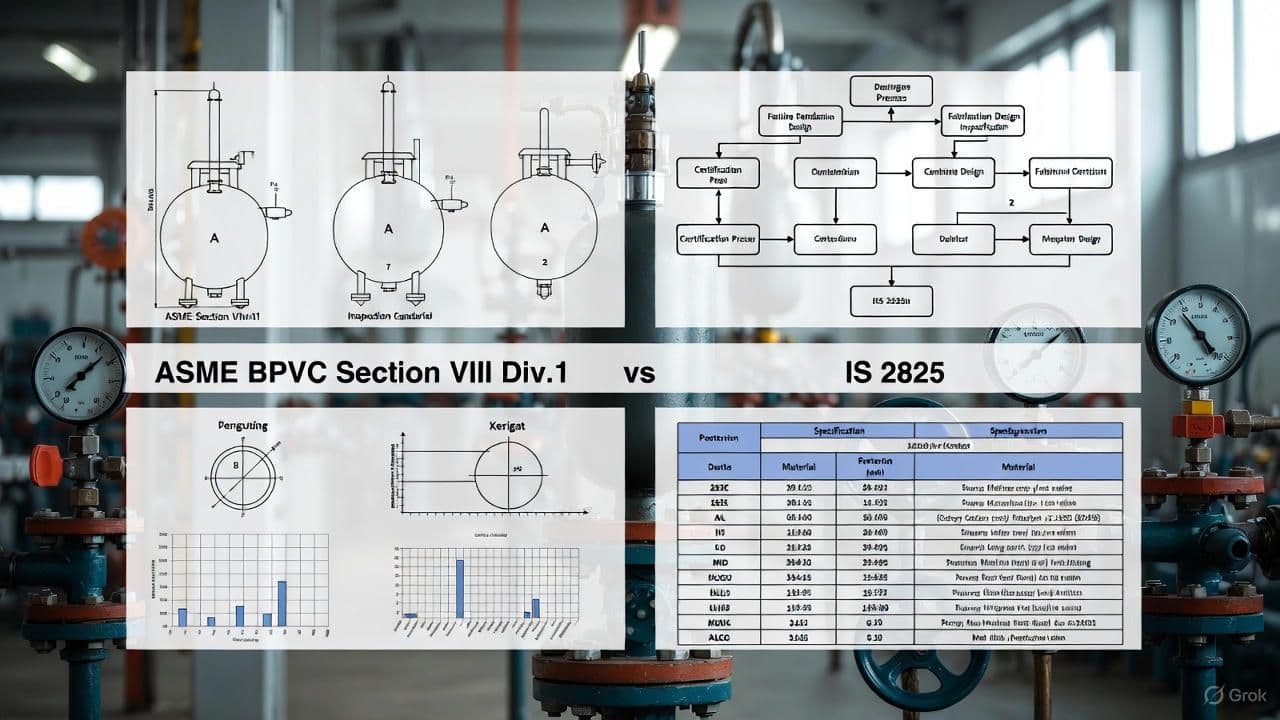

ASME Section VIII vs IS 2825 — Comparative Analysis

Comparative Analysis of ASME BPVC Section VIII and IS 2825 Pressure Vessel Codes

Scope: Side-by-side engineering-focused comparison covering code philosophy, material/allowable stress basis, principal design formulas, fabrication/welding & PWHT, inspection & testing, marking/certification, and practical implications for design/fabrication engineers.

1.0 Executive summary

ASME BPVC Section VIII, Div.1 and IS 2825 both provide complete design-by-rule frameworks for pressure vessels but differ in philosophy and specific technical rules. IS 2825 uses a class-based, duty-driven structure (Class 1-3) and allows allowable stresses based on yield or tensile with lower safety factors in some cases; ASME applies a material- and service-driven approach using tabulated allowable stresses (Section II) and a generally more conservative tensile-based factor for internal pressure. These differences affect thickness, weight, NDE scope, PWHT practice, and documentation paths - all of which have direct cost, manufacturability, and compliance implications for international projects.

2.0 Foundational philosophy & classification

2.1 IS 2825 - tiered, duty-driven

- Classes:

- Class 1: Highest duty - strictest design, fabrication, inspection.

- Class 2: Medium duty - moderate requirements; spot radiography requirements for key joints.

- Class 3: Light duty - plate thickness ≤ 16 mm and limits on vapor/hydrostatic pressures (e.g., working vapor ≤ 3.5 kgf/cm² or hydrostatic ≤ 17.5 kgf/cm²).

- Design drivers: Duty/class determines inspection extent and some fabrication rules.

2.2 ASME Section VIII, Div.1 - material/service-driven

- No tiered class system; uses parts and P-Numbers (e.g., UCS, UHA) and material tables in ASME II for allowable stresses.

- Special service provisions (e.g., lethal service) add rule layers.

- Design drivers: material group, temperature, service, and tabulated stress values.

Practical implication: IS 2825's class approach ties inspection & QA early to service; ASME centralizes design conservatism in its material tables and service-specific clauses.

3.0 Material requirements & allowable stress criteria

3.1 Philosophical difference - basis of allowable stress

- IS 2825: allowable stress is the lower of (certified minimum yield / factor) or (specified minimum tensile / factor). Typical safety factors: yield/1.5 and tensile/3.0 for carbon steels; other factors vary by material group (see table below).

- ASME Sec VIII Div.1: allowable stress for internal pressure is primarily derived from specified minimum ultimate tensile strength using a safety factor (commonly 3.5 for many ferrous materials) and, more practically, directly from tabulated S values in ASME Section II, Part D for materials at temperature.

3.2 Consequences

- For identical material properties and pressure, ASME can produce thicker required walls (more conservative tensile-based limit) compared to IS 2825 where yield-based provision may permit thinner sections.

- ASME's tabulated stress values (S) simplify design iterations and are temperature-dependent; IS 2825 requires more direct computation using stated material minima.

4.0 Key design formulas & comparisons

4.1 Cylindrical shell under internal pressure

ASME formula (common form):

Where:

- = required thickness (m)

- = internal design pressure (MPa)

- = internal radius (m)

- = allowable stress (MPa)

- = joint efficiency (0 < E ≤ 1)

IS 2825: similar thick-walled thin-shell equations exist but allowable stress determination and some shape factors differ. IS 2825 also uses shape factors and charts more actively for formed heads.

Worked example (step-by-step arithmetic)

Design for: , , , .

- Compute numerator: .

- Compute .

- Compute denominator: .

- Compute thickness: .

- Convert: .

- Apply corrosion allowance and rounding per code (e.g., + corrosion allowance 1.5 mm ⇒ design thickness ≈ 15.912 mm ⇒ select nearest standard plate/thickness per fabrication practice, e.g., 16 mm).

Important: arithmetic shown digit-by-digit to avoid rounding errors.

4.2 Formed heads (torispherical / elliptical)

- ASME (torispherical approximate):

where (L) is a characteristic length (often crown radius or equivalent).

- IS 2825: uses a geometry-dependent shape factor (c) taken from a chart (e.g., Fig. 3.7) so required thickness for heads is not strictly linear with crown radius; designers must consult the IS chart to get (c).

Implication: IS 2825 allows more geometry optimization via charts; ASME uses closed-form coefficients.

4.3 Openings & reinforcement

- Both codes implement area-replacement for nozzle reinforcement (ASME UG-37 and IS 2825 Fig. 6.6).

- IS 2825 explicitly allows uncompensated small openings ≤ 0.05 m diameter and provides charts to determine maximum uncompensated opening vs shell diameter - a practical advantage for small nozzles.

- ASME defines tabulated allowable reinforcement limits and dimensional checks; designers typically follow UG-37 and associated figures.

4.4 External pressure (vacuum) design

- ASME: iterative use of external pressure charts (Factors A and B), combined with material charts (e.g., NF curves) - conservative, graphically driven, accounts for elastic buckling and plastic collapse, includes safety factors (commonly 3.0 on buckling).

- IS 2825: provides direct formulae for allowable external pressure and for moment of inertia requirements for stiffening rings - more formulaic and sometimes simpler to apply for standard geometries.

4.5 Flanges & supports

- Flanges: IS 2825 classifies loose, integral, optional, and checks for two load cases: operating and bolting-up. ASME uses stress component checks (e.g., hub stresses) against flange material allowable (Sf).

- Supports: Both give detailed rules (e.g., saddle design factors K3/K4 in IS 2825; ASME has nonmandatory appendices and guidance). Use of local stiffeners, saddle contact area and thermal expansion provisions must follow the chosen code.

5.0 Fabrication, welding, and PWHT

5.1 Welding procedures & qualifications

- Both codes require WPS, WPQ and procedure/welder qualification: ASME references Section IX; IS 2825 references its Section 7 and relevant standards. Qualification tests and acceptance criteria are explicit.

5.2 PWHT (Post-Weld Heat Treatment) - specific contrasts

| Topic | IS 2825 (prescriptive) | ASME VIII-1 (material tables) |

|---|---|---|

| Holding temperature (example) | 580-620 °C (prescriptive) | Table UCS-56: depends on P-No and material; e.g., some steels ~540 °C (1,000 °F) |

| Furnace entry rule | Furnace must be ≤ 300 °C when vessel moved inside | Not prescriptive in same wording; uses material-based guidance and time-at-temperature rules |

| Heating rate (example) | ≤ 220 °C/hour above 300 °C for thickness ≤ 25 mm (prescriptive) | ASME provides time-at-temperature guidance; lower temp/longer time allowed per table |

Practical impact: IS 2825's prescriptive cycle can require different furnace controls and may lengthen or complicate scheduling relative to ASME's material-based, tabulated approach.

6.0 Inspection, examination & testing

6.1 Inspection stages & NDE

- IS 2825: inspection scope is class dependent (Table 1.1). E.g., Class 2 mandates spot radiography on butt joints of categories A & B; Class 1 has more extensive radiography/UT.

- ASME: NDE extent depends on joint category, thickness, material, and joint efficiency; ASME UG and Appendix dictate radiography, ultrasonic, magnetic particle, dye penetrant, etc. Generally, ASME is less prescriptive by "class" and more by construction/efficiency criteria.

6.2 Hydrostatic & destructive-test provisions

- Hydrostatic test is mandatory in both. ASME includes specific clauses (UG-99 and UCD-115) that require at least 2× MAWP for vessels designed on destructive test data. IS 2825 has its hydrostatic test rules tied to class and service.

6.3 Records & traceability during inspection

- IS 2825 emphasizes class-based inspector involvement and “Certificate of Manufacture and Test”. ASME reliance on Manufacturer's Data Report (e.g., Form U-2A) and stamping is the standard route.

7.0 Marking, certification & documentation

| Item | IS 2825 | ASME VIII-1 |

|---|---|---|

| Marking | Stamp or permanent nameplate; nameplate mandatory for plates < 7 mm | UG-115 to UG-120 dictate required stamping/nameplate content (ASME code stamp, manufacturer, MAWP, serial no., year) |

| Certificate | "Certificate of Manufacture and Test" mandatory | Manufacturer's Data Report (Form U-2A) and ASME U-stamp for certified shops |

| Traceability | Emphasized per class and test reports | Emphasized via heat-no., mill certificates, WPS records, and U-stamp documentation |

Note: For cross-jurisdiction projects, both sets of documents should be prepared and cross-referenced to satisfy client, local authority, and insurer requirements.

8.0 Practical rules of thumb & typical ranges

- Allowable stress difference: Expect ASME to yield larger required thickness (often ~5-20% higher) for many carbon steels versus an IS 2825 design that uses yield-based limits; magnitude depends on material tensile vs yield ratio and design pressure.

- Small nozzle rule: If many small nozzles ≤ 50 mm exist, IS 2825’s uncompensated-opening provisions may reduce reinforcement material over ASME approaches.

- PWHT planning: If vessel requires PWHT per IS 2825 (prescriptive), budget longer furnace cycles and ensure furnace entry temp control (≤ 300 °C) and slow controlled heating above 300 °C.

- NDE cost: Class-driven NDE in IS 2825 can increase radiography costs if high class is specified; ASME may achieve equivalent assurance via UT + accepted joint efficiencies.

- Support design: For horizontal vessels > 2.5 m diameter, check IS 2825 saddle formulas (K factors) vs ASME recommendations - saddle bending and local shell stresses often control skirt thickness.

9.0 Worked example - comparative thickness estimate (illustrative)

Design conditions:

- Internal pressure

- Internal radius

- Material: Carbon steel with (tabulated), IS allowable (yield/tensile basis) assumed 160 MPa for demonstration (depends on selected safety factor).

Using ASME formula (as earlier) with and :

- (raw, before CA & weld reinforcement)

Using IS formula with :

- Denominator: MPa

- Numerator: MPa·m

Interpretation: For these assumed S values, IS design thickness ≈ 12.6 mm vs ASME ≈ 14.4 mm - about 14% thinner before corrosion allowance and fabrication rounding. Actual difference depends on material S values used and joint efficiency.

10.0 Figure suggestions (for reports / presentations)

- Figure 1: Flow chart contrasting decision path: IS 2825 (Class → Design rules → NDE scope) vs ASME (Material/P-No → S-tables → Service clauses).

- Figure 2: Side-by-side graph of allowable stress vs temperature for a representative carbon steel from ASME Section II vs computed IS allowable stress (yield/tensile basis).

- Figure 3: Chart showing nozzle reinforcement “uncompensated opening” limit vs shell diameter per IS 2825 and ASME UG-37 equivalent limits.

- Figure 4: PWHT cycle comparison timelines (IS prescriptive cycle vs ASME table-based time/temperature profiles).

11.0 Code selection - decision matrix (practical guide)

| Project factor | Prefer IS 2825 | Prefer ASME VIII-1 |

|---|---|---|

| Primary market: India / local regulatory requirement | ✅ | ❌ |

| Need for class-based QA & inspector involvement | ✅ | ⚠️ (ASME workable but different) |

| Need for international acceptance/owner spec outside India | ⚠️ | ✅ (ASME U-stamp globally accepted) |

| Many small nozzles where uncompensated openings save cost | ✅ | ⚠️ |

| Preference for tabulated S values & global material library | ⚠️ | ✅ |

| Conservative tensile-based allowable stress (higher safety) needed | ⚠️ | ✅ |

(✅ = strong fit, ⚠️ = conditional, ❌ = less appropriate)

12.0 Practical recommendations for design & fabrication engineers

- Define project code early. Choose code at FEED stage to lock material choices, NDE schedule, and procurement documents.

- Cross-check material S values. If switching between IS and ASME, compute S_IS and S_ASME for candidate materials and quantify mass/price differences.

- Plan NDE & inspector access. IS 2825 Class requirements may require owner/third-party inspector presence and additional radiography. Include in procurement schedule.

- PWHT capability check. Confirm local furnaces can meet IS 2825 prescriptive heating-rate and entry-temperature rules if IS code is used.

- Document mapping for export. For vessels to be used in multiple jurisdictions, prepare both code traceability documents (Manufacturer's Data Report + Certificate of Manufacture & Test) and show equivalencies for inspections/weld qualifications.

- Perform a baseline comparative estimate (material weight, labor, NDE cost, PWHT cycle time) to quantify cost difference before finalizing the code.

13.0 Conclusion - synthesis of major technical differences

- Philosophy: IS 2825 uses duty classes; ASME uses material/service & tabulated S values.

- Allowable stress: IS may permit yield-based allowances (thinner shells in some cases); ASME generally applies a tensile-based conservative view via its S tables.

- Design rules: Formulas are similar in spirit, but head thickness charts (IS) vs coefficients (ASME) and external pressure methods differ.

- Fabrication & PWHT: IS is more prescriptive in PWHT cycles; ASME uses material-based tables.

- Inspection & NDE: IS ties NDE scope to class; ASME ties to joint type, efficiency, thickness, and material.

- Documentation: Different mandatory certificate formats and marking practices exist; plan for both for cross-border projects.

Appendix A - Quick comparison table

| Topic | IS 2825 | ASME VIII-1 |

|---|---|---|

| Classification | Class 1,2,3 (duty-based) | No class; material & service driven |

| Allowable stress basis | Yield/tensile with varying safety factors | Ultimate tensile/tables (ASME II) - conservative |

| Head design | Shape factor charts (geometry dependent) | Formulaic coefficients (e.g., torispherical 0.885 factor) |

| Small openings | Uncompensated openings ≤ 0.05 m allowed (chart-based) | Area replacement rules; more conservative limits |

| External pressure | Direct formulae for allowable external pressure | Chart-based method with Factors A & B and NF curves |

| PWHT | Prescriptive cycles (temperatures, heating rates) | Table-based per P-No and thickness |

| NDE scope | Class dependent (Table 1.1) | Joint/material/thickness dependent |

| Certification | Certificate of Manufacture & Test | Manufacturer's Data Report; U-stamp |

References & standards (for procurement / engineering office)

- ASME Boiler & Pressure Vessel Code, Section VIII, Division 1; ASME Section II (Materials); ASME Section IX (Welding).

- IS 2825:1987 (Pressure vessels - code of practice) and subsequent amendments/revisions.

- Local regulations & owner specifications - always confirm applicable statutory requirements and owner code addenda.

Final notes

- This document is an engineering-focused synthesis and does not replace the word-for-word reading of the respective code books. Always consult the latest published code editions, addenda, and local statutory requirements before final design/fabrication.