What is a Cooling Tower and How Does it Work?

What is a Cooling Tower and How Does it Work?

An In-Depth Guide for Process and Chemical Engineers

Cooling towers are essential elements in modern industrial plants. From power stations to chemical refineries and HVAC systems, they form the backbone of heat rejection, ensuring stable operation and process integrity. Yet, many engineers underestimate the complexity and science behind their operation.

This comprehensive guide explores cooling tower fundamentals, heat and mass transfer principles, tower types, engineering calculations, troubleshooting, and advanced optimization strategies.

Introduction: Why Use Cooling Towers?

Heat is an unavoidable byproduct of nearly all industrial processes - exothermic reactions, compression, distillation, and condensation all generate energy that must be removed.

If uncontrolled, this heat causes equipment damage, safety risks, and process inefficiency.

Cooling towers offer the most energy-efficient and cost-effective method for rejecting large amounts of heat by evaporative cooling, where a small portion of water is vaporized, removing the latent heat of vaporization from the rest.

What Is a Cooling Tower?

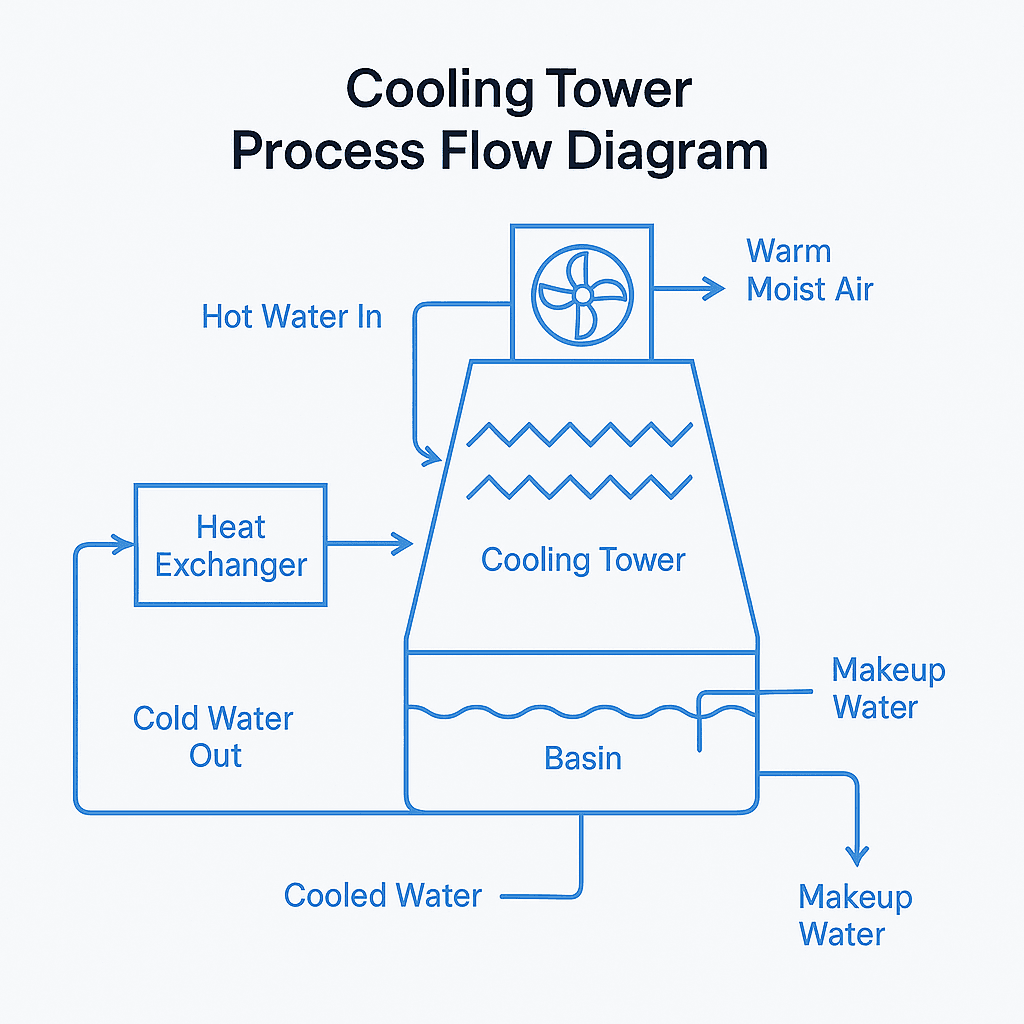

A cooling tower is a heat rejection device that extracts waste heat from water by bringing it into direct or indirect contact with air, lowering the water’s temperature through partial evaporation.

Core Functions:

- Accepts hot water from process equipment or condensers.

- Exposes water to large volumes of air for evaporation.

- Returns cooled water to the process loop.

Fundamental Working Principle - Evaporative Cooling

Cooling towers operate on the principle that a small fraction of water evaporates, carrying away its latent heat and cooling the remaining bulk liquid.

- Hot water is distributed into droplets through spray nozzles or fill media.

- Air moves (naturally or via fans) across or upward through these droplets.

- Around 1-2 % of water evaporates, removing latent heat (~2260 kJ/kg at 100 °C).

- The cooled water collects at the bottom basin and is recirculated.

Thermodynamic Concept:

Evaporative cooling allows the water temperature to drop below the dry bulb temperature, approaching the wet bulb temperature (WBT) as the theoretical limit.

Key Components of a Cooling Tower

| Component | Function |

|---|---|

| Hot Water Inlet | Receives warm water from process heat exchangers or condensers. |

| Distribution System | Sprays or evenly distributes water across fill media. |

| Fill Media | Increases surface area for air-water contact (splash bars or film fill). |

| Drift Eliminators | Capture entrained droplets to reduce drift losses. |

| Air Inlet | Allows ambient air entry, usually at the base or sides. |

| Fan (Mechanical Draft) | Induces or forces airflow through the tower. |

| Basin | Collects cooled water; includes makeup and blowdown controls. |

| Structure/Casing | Provides mechanical support and enclosure. |

Types of Cooling Towers

1. Natural Draft Cooling Towers

- Airflow is induced by the buoyancy (chimney effect) of warm air.

- Typically hyperboloid in shape (100 m+ tall).

- Ideal for power plants - large capacity, no fan energy cost.

2. Mechanical Draft Cooling Towers

- Use fans to move air through the tower.

Induced Draft:

Fan on top “pulls” air upward → better efficiency.

Forced Draft:

Fan at base “pushes” air into the fill → easier to install but prone to recirculation.

By airflow:

- Counterflow: Air moves upward opposite to water. Compact and efficient.

- Crossflow: Air moves horizontally across falling water. Easier maintenance.

3. Closed-Circuit (Fluid) Towers

- Process fluid (e.g., glycol, brine) circulates inside a coil; water flows over it.

- Prevents contamination and scaling in process fluids.

4. Hybrid and Modular Towers

- Combine dry and wet cooling for water conservation or seasonal operation.

- Modular designs enable scalable installations.

Cooling Tower Water Cycle - Key Flows

Every cooling tower balances several streams:

- Recirculating Water: Main process loop.

- Makeup Water: Replaces evaporative, blowdown, and drift losses.

- Blowdown (Bleed): Removes high-TDS water.

- Drift: Droplets carried out with exhaust air.

Typical losses:

Cooling Tower Design - Psychrometric Fundamentals

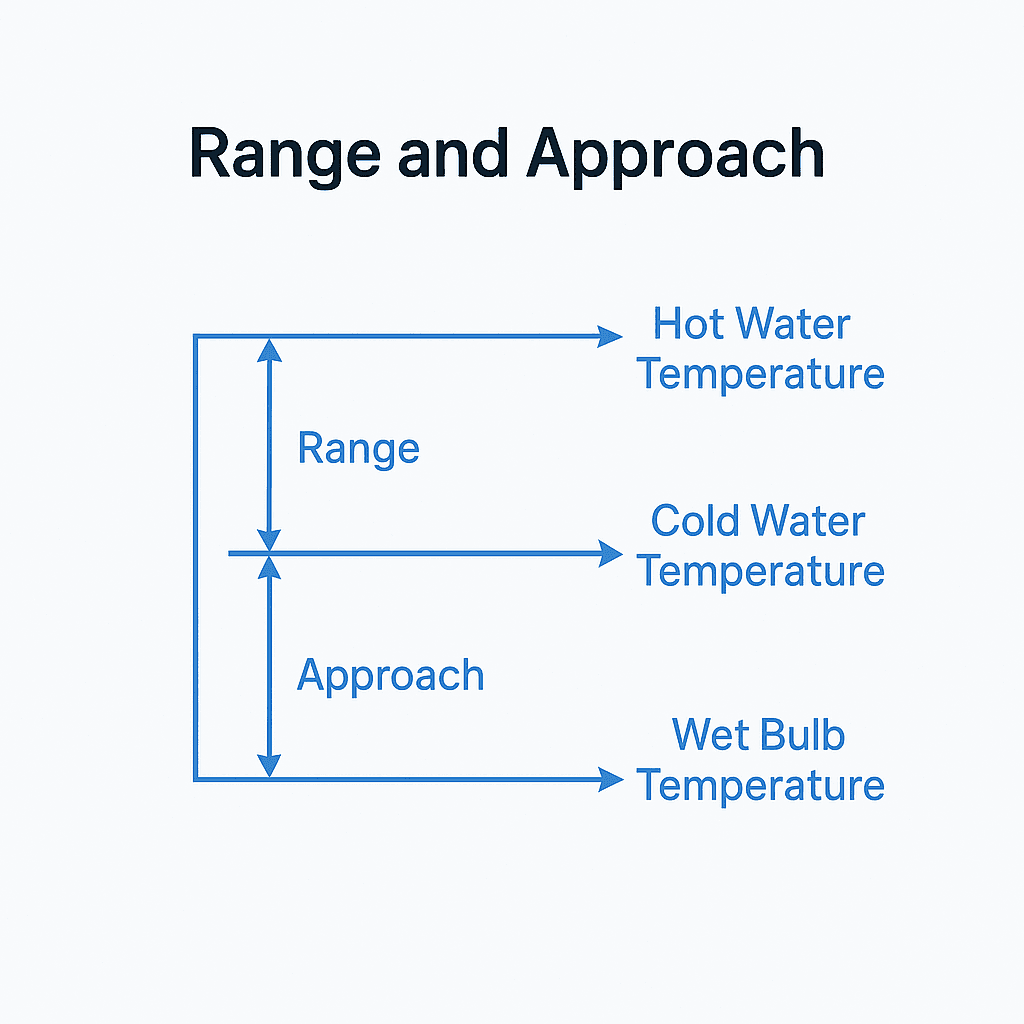

Cooling performance is limited by the ambient wet bulb temperature (WBT).

Approach

A smaller approach means better cooling (larger, more efficient tower).

Range

Example:

If , , and

Step-by-Step Working of a Cooling Tower

- Hot Water Delivery - Water from process units enters the tower.

- Distribution & Breakup - Sprays or trays disperse water for fine droplet formation.

- Fill Section - Water trickles down fill media, maximizing air contact area.

- Air Flow - Fans or buoyancy drive air across the falling water.

- Evaporation & Cooling - A small portion evaporates, removing latent heat.

- Collection - Cooled water collects in the basin for recirculation.

- Drift Control - Eliminators trap droplets to prevent water losses.

- Makeup & Blowdown - Maintain water balance and control TDS.

Cooling Tower Performance Equations

1. Heat Load

Where:

- = heat load [kW or kJ/h]

- = water mass flow rate [kg/s]

- = specific heat ≈ 4.186 kJ/kg·K

- = temperature drop [°C]

2. Evaporation Loss

3. Cycles of Concentration (CoC)

Blowdown Rate:

4. Fan Power (Mechanical Draft)

Where:

- = air volume flow [m³/h]

- = pressure rise [Pa]

- = fan efficiency

Key Factors Affecting Performance

| Parameter | Influence |

|---|---|

| Wet Bulb Temperature | Dictates theoretical minimum temperature. |

| Tower Size / Fill Type | Larger or structured fill increases heat transfer area. |

| Airflow Volume | More air → more evaporation → better cooling. |

| Water Distribution | Uniform spray prevents hot spots. |

| Blowdown Control | Prevents scaling, corrosion, and biological fouling. |

| Drift Eliminators | Reduce water and chemical losses. |

Troubleshooting: Common Cooling Tower Issues

| Problem | Likely Cause | Recommended Solution |

|---|---|---|

| High Cold Water Temperature | Dirty fill, poor airflow, high WBT | Clean fill, increase fan speed |

| Scaling | High TDS, poor blowdown | Increase blowdown, optimize water chemistry |

| Biological Fouling | Warm stagnant water | Apply biocide/shock dosing |

| Excessive Drift | Damaged eliminators | Repair eliminators, add wind screens |

| Noise/Vibration | Fan imbalance | Balance fans, lubricate bearings |

| Visible Plume | High humidity + low ambient | Install plume abatement modules |

Cooling Towers in Integrated Plant Operation

Applications:

- Process Cooling: Compressors, reactors, exchangers.

- Power Plants: Condenser cooling.

- HVAC: Air conditioning and building systems.

- Recycling: Effluent or blowdown recovery.

Design Considerations:

- Correct loop hydraulics and NPSH.

- Water treatment for corrosion control.

- Redundancy (multi-cell towers).

- Digital monitoring and predictive maintenance.

Environmental and Regulatory Factors

| Concern | Description |

|---|---|

| Water Consumption | Evaporative losses minimized by hybrid systems. |

| Drift Emissions | Controlled for Legionella prevention. |

| Noise & Plume | Compliance with environmental norms. |

| Blowdown Disposal | Managed per local discharge regulations. |

Advanced Developments

- Smart Controls: IoT-based adaptive fan and blowdown control.

- Modular Towers: Prefabricated for rapid deployment.

- Hybrid Designs: Air + evaporative for water savings.

- Materials Innovation: FRP, stainless steel, and plastics enhance lifetime and hygiene.

Step-by-Step Cooling Tower Sizing Example

Given:

- Circulating water = 600 m³/h

- Inlet temperature = 42 °C

- Outlet temperature = 32 °C

- Ambient WBT = 27 °C

- CoC = 4

1. Heat Load

2. Evaporation Loss

3. Blowdown

4. Makeup Water

Assume drift = 0.05 % of circulation:

Conclusion

Cooling towers are far more than simple “heat dumpers.” They embody a combination of thermodynamics, fluid mechanics, and environmental science.

Proper understanding ensures reliability, efficiency, and sustainability in modern plants.

By mastering psychrometrics, cycles of concentration, and smart controls, engineers can design systems that minimize water and energy use while maximizing uptime.

References

- Perry’s Chemical Engineers’ Handbook, 9th Edition

- Cooling Tower Institute (CTI) Technical Manuals

- ASHRAE Handbook - HVAC Systems and Equipment

- U.S. EPA: Cooling Tower Fundamentals

- ASME Process Design Standards